About Parco Engineers

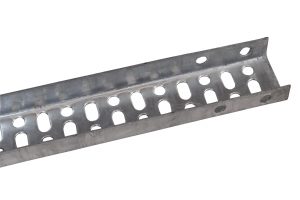

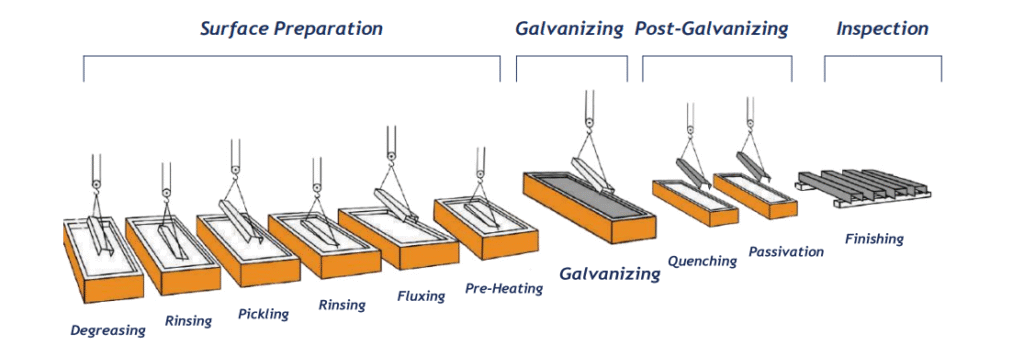

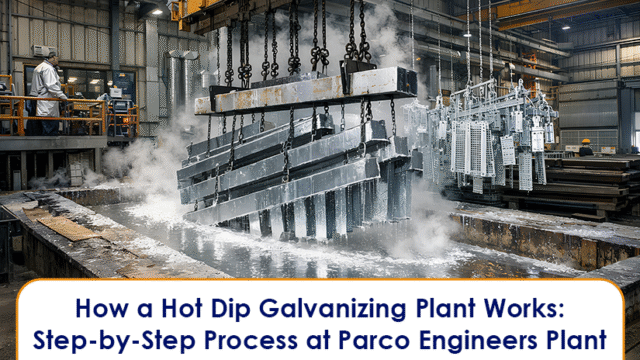

Established in 1999, PARCO ENGINEERS (MUMBAI) PRIVATE LIMITED initially focused on iron and steel trade for infrastructure and utility projects. Over time, we partnered with other enterprises to expand into the manufacturing of Hot Dip Galvanized Iron and Steel products which include Galvanized Structures, Handrails, Cable Trays, Gratings and various Fabricated Structures.

At PARCO, customer satisfaction is our foremost priority, and quality is the foundation of our operations. We are dedicated to providing superior products, complemented by robust after-sales service to nurture long-lasting customer relationships. Our commitment goes beyond just delivering high-quality solutions — we aim to build trust, confidence and customer satisfaction with every interaction.

Our management system is aligned with globally recognized ISO 9001:2015, 14001:2015, and 45001:2018, reflecting our unwavering dedication to quality and excellence.