Art of Galvanization: Elevating Durability with Zinc Coatings

Galvanization is a transformative process that coats steel or iron with zinc, providing it with the highest protection against rust and corrosion. It combines science and innovation to create durable materials that can endure harsh environments and maintain performance and longevity. Zinc’s unique properties make it indispensable in offering corrosion resistance as it prevents moisture and oxygen from reaching the metal underneath. It also heals itself because scratched zinc leaves behind a layer of protecting oxide. Plus, because zinc is recyclable, it’s an environmentally-friendly practice to use the hot dip galvanized products in industries that desire long-life products with fewer maintenance hassles.

Galvanized materials are very crucial in many industries. In construction, galvanized coating are used to make strong bridges, beams, and roofing. In the automotive industry, they are used to protect vehicle parts from wear and corrosion. Agriculture also benefits from strong tools and fences that resist chemicals and weather. In the energy sector, galvanization increases the life of solar structures, pipelines, and wind turbines.

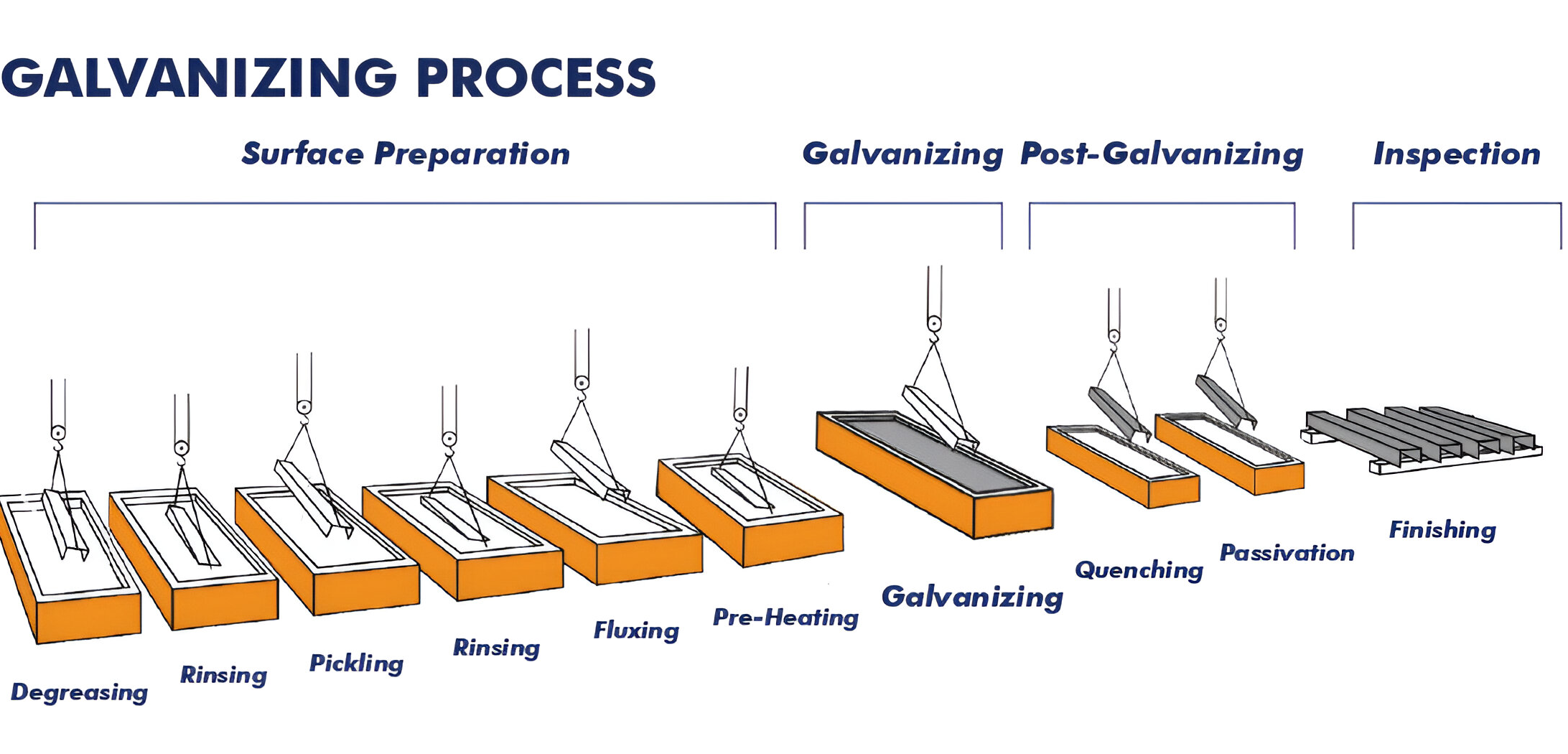

The galvanizing process starts with surface preparation to ensure that zinc adheres well, then hot-dip galvanized products are formed, where metals are immersed in molten zinc to create a thick protective galvanized coating. Finally, there is stripping off excess zinc and conducting quality checks to ensure the best results. This process produces durable, reliable, and aesthetically pleasing materials that require little upkeep, reducing long-term costs and environmental impact.

Parco Engineers offer superior galvanized sheets and hot dip galvanized products for industrial and personal project needs. Whether you need durable material for large-scale infrastructure projects or lightweight components for high-precision applications, services provided here ensure robustness, sustainability, and aesthetic appeal in the final product. Let us at Parco Engineers upgrade your materials and projects with top quality galvanized coating.

Exploring the Spectrum: Diverse Galvanized Products and Their Distinctive Traits

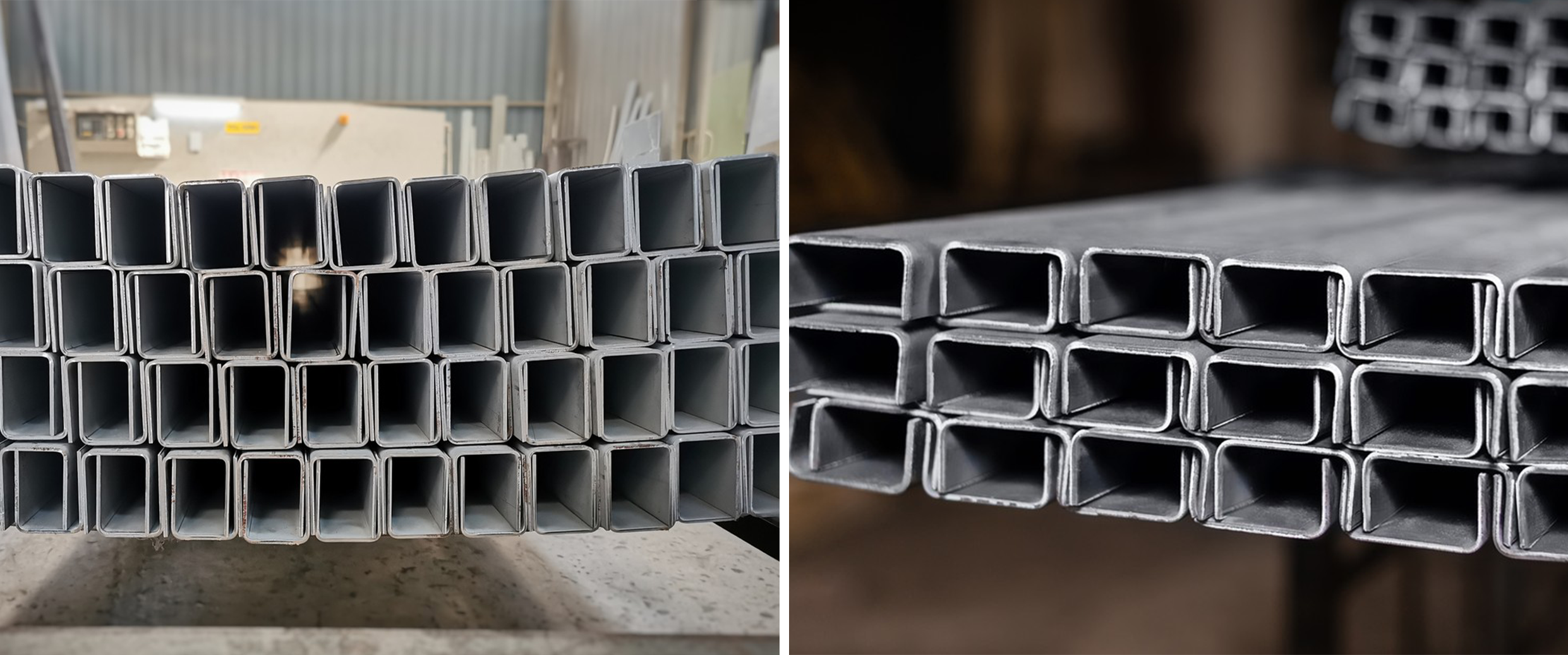

Galvanizing process changes plain materials into reliable products which are very essential in several sectors of the economy. Due to strength and versatility, steel galvanized sheets and coils come to great importance in constructions, auto industries, household appliances which provide roofing and casing.

Galvanized pipes are widely utilized in water supply, irrigation, and construction as they can resist corrosion significantly longer and are very durable besides being cheaper in comparison with stainless steel.

Galvanized wires used for fencing electrical installations, industrial applications, as well are also appreciated for very high tensile strength, outstanding flexibility besides corrosion resistance of outdoor applications.

Galvanized gratings and mesh, required for flooring and safety enclosures, resist slipping, carry heavy loads and can withstand the elements, ensuring they are great for industries and coastal uses.

On the other hand, the galvanized hardware and fasteners like nuts, bolts, and screws stand out because they last longer, do not change color or look old due to their polish even when faced with extreme conditions.

These diverse hot dip galvanized products enhance performance, reduce maintenance, and ensure longevity and are therefore critical for a range of applications.

At Parco Engineers, we specialize in delivering premium galvanized coating solutions tailored to your specific needs.

Why Galvanized? Unveiling the unmatched advantages of Zinc-infused materials.

Galvanization is the process of coating steel or iron with zinc, enhancing the durability, cost efficiency, and versatility of materials across industries. The galvanizing process forming the galvanized steel metal offers unmatched protection against rust and corrosion because zinc acts as a shield to prevent moisture and oxygen from reaching the underlying metal. Hot Dip Galvanized products retain their integrity much longer than untreated alternatives even in the most severe environments, such as coastal areas or industrial zones.

Galvanized materials require very little maintenance, which makes them a cost-effective investment for small and large-scale projects, for example galvanized iron and galvanized steel. One of the most notable features of zinc coatings is their self-healing property, if scratched or chipped, zinc sacrifices itself to form a protective oxide layer, thus ensuring that the underlying metal remains secure.

Hot Dip Galvanized products like galvanized iron find applications in various sectors such as building construction (beams, roofing, and structural elements), automotive (body panels and parts), agriculture (fences, tools, silos), and energy (pipelines, wind turbines, and solar structures).

In addition, the benefits of galvanized steel is that it’s also an environmentally friendly process because zinc can be 100% recycled, and the long lifecycle of galvanized coating or galvanized products cuts down on waste and saves resources. With durability, versatility, and sustainability, galvanized products like galvanized iron, galvanized steel are a perfect answer to the needs of modern industries.

At Parco Engineers, as a cable ladder manufacturer and ms sheets we have the specialized expertise in providing high-quality, galvanized zinc coating materials to meet your particular project needs.

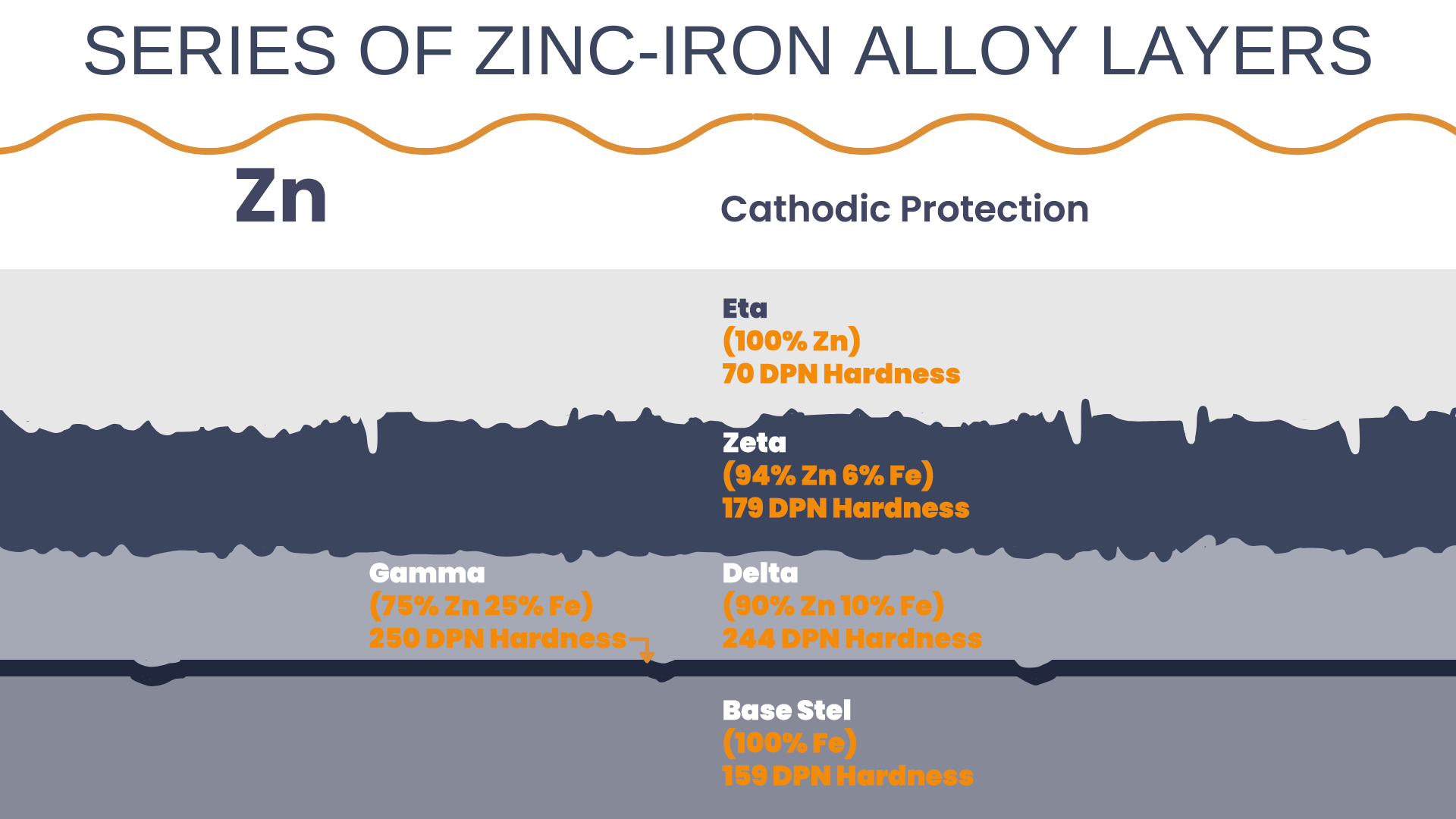

Enduring Protection: How Galvanization Shields Against the Elements

Galvanization is a reliable process that strengthens steel and iron with a protective glavanized zinc coating, creating galvanized steel metal with a robust barrier against environmental elements. This galvanizing process shields metals from moisture, oxygen, extreme weather, and industrial pollutants to ensure unmatched durability and long-term protection. The galvanizing process works by coating metals with zinc, which acts as a sacrificial layer to prevent rust. This galvanized zinc coating prevents moisture and oxygen from reaching the metal at its base, and in harsh conditions, it consumes its share of corrosion instead, preserving the structural integrity and prolonging its lifespan.

Galvanized materials excel in preventing the penetration of different types of elements. Zinc prevents water, which reduces rust and maintains material strength in wet or damp conditions. Further, it slows down oxidation, hence, it prevents the corrosion that is caused due to oxygen exposure. Galvanized steel metal performs excellently even in extreme climates, including coastal environments with salty air or industrial settings filled with pollutants. It also resists mechanical wear and tear due to the robust galvanized zinc coating, which makes them suitable for demanding applications.

Galvanized products are also very necessary in construction because they have the strength and durability for structural beams, bridges, and roofing materials. For agriculture, the galvanized tools, fencing, and silos can be trusted for long corrosion protection. Automotive industries also need galvanized body panels and parts, and the energy sector depends on pipelines, wind turbines, and solar panel structures for durable applications.

Galvanized materials like galvanized iron and galvanized steel metal come with not only durability and minimal maintenance but also sustainability because zinc is completely recyclable, and therefore it is an eco-friendly material to use. At Parco Engineers, we are are the top most cable ladder supplier specialize in offering high-quality, zinc-coated solutions designed to face the elements and protect your investments.

Hot-Dip vs. Electro-Galvanization: A Clash of Coatings

When it comes to protecting metals from rust and corrosion, two widely used methods are Hot-Dip Galvanization (HDG) and Electro-Galvanization. While both involve coating steel or iron with zinc, their techniques, benefits, and applications differ significantly.

Hot-Dip Galvanization (HDG) involves immersing steel or iron in molten zinc to create a thick, durable galvanized zinc coating that bonds strongly with the metal forming the galvanized iron and galvanized steel metal. This process provides excellent corrosion resistance, especially in outdoor and industrial environments. The thick coating guarantees decades of strong protection, while zinc’s self-healing ability enables it to protect the underlying metal even if the surface is scratched. Hot Dip Galvanization is very cost-effective for large projects and is used for most structural steel in construction, outdoor fencing, bridges, pipelines, power towers, and industrial equipment.

Electro-galvanization is a process in which an electric current is used to deposit a thin, uniform layer of zinc onto the metal surface. This process creates a sleek, polished finish, making it ideal for applications where aesthetic appeal is a priority. Electro-galvanization provides consistent coating thickness, which is perfect for intricate shapes and small components. Its lightweight nature makes it suitable for precision applications such as automotive body panels, nuts, bolts, screws, and indoor furniture or appliances.

The choice between these options depends on the application. Hot-Dip Galvanization is ideal for heavy-duty durability and outdoor applications, while Electro-Galvanization is more suitable for lightweight, precise, and ornamental applications. At Parco Engineers, we cater to your specific needs, offering both Hot-Dip Galvanization and electro-galvanization services.

At Parco Engineers, we take pride in being a trusted partner for iron traders and a leading cable ladder manufacturer, GI strips, perforated cable tray, ladder type cable trays, cold rolled sheets manufacturer in the industry. With years of expertise, we specialize in delivering high-quality products that meet the evolving demands of construction, infrastructure, and industrial projects.

Our extensive product range includes premium handrails, GI strips, chequered plates, perforated cable trays, GI cable trays, ladder type cable trays which are widely preferred by iron traders for their superior durability and resistance to corrosion. Whether you need GI cable trays or perforated cable trays, we ensure that each product is crafted with precision, offering unmatched strength and reliability for various electrical installations.

For industries that need robust solutions, our handrails, ladder type cable trays and GI strips stand out because of their excellent load-bearing capacity and ease of installation. As a reputable cable ladder supplier, we provide products engineered to meet stringent quality standards, making them ideal for large-scale electrical and communication networks.

Apart from our cable management systems, we also provide high-quality chequered plates and checkered plates. These are used in industrial flooring applications and ensure better safety due to their anti-slip design. Our chequered plates, cold rolled sheets and GI cable tray are highly durable and are in high demand among iron traders.

Parco Engineers also designs and manufactures quality handrails, GI strips and chequered plates to ensure safety at every step, on all platforms, walkways, and industrial facilities. Our handrails are robust, supporting heavy use while ensuring the highest standards of industry safety norms.

We are a reliable cable ladder manufacturer and strive for innovation in product lines while making constant improvements. Cable ladders, ladder type cable trays and GI cable trays offer support for heavy cables and facilitate easy maintenance.

Whether you’re an individual contractor or a large corporation, Parco Engineers is your one-stop solution for GI strips, chequered plates, GI cable trays, perforated cable trays, ladder type cable trays, handrails, cold rolled sheets, ms sheets and reliable cable management systems. Our commitment to quality, precision, and customer satisfaction has made us a go-to choice for iron traders and industry professionals alike.

We specialize in delivering top-quality products designed to meet the diverse needs of various industries. Our expertise lies in providing high-grade materials and components that enhance structural integrity and durability across a range of applications.

Stainless Steel Handrail Solutions

Our premium stainless steel handrail systems have always been built to provide both safety and aesthetic appeal. And whether for residential or industrial usage, the handrails have always managed to be very strong while maintaining a sleek, modern look. Our robust base plate designs now make installation far safer and more efficient, giving your stainless steel handrail setups more stability.

High Quality Base Plate and Round Bar Components

We have a range of base plates tailored to different load-bearing requirements. These plates are precision engineered for the effective support of structural components. Our round bars are also available in various sizes, offering flexibility for an array of construction projects. Round bar products provide the best strength and versatility for frameworks that are mainly decorative or structural support.

Galvanized Steel and Solar Structures

At Parco Engineers, we recognize the value of durability in outdoor applications. Our galvanized square steel products are treated with advanced galvanization techniques to offer superior corrosion resistance. These components are ideal for building solar structure frameworks that endure harsh environmental conditions.

Cold Rolled sheets and GP Sheets for Precision Applications

Our cold rolled sheet (cr sheet) has outstanding smoothness and regularity of the thickness, as the product demands accuracy for those applications. Hence, the finished product can be more accurate with sheets. GP SHEETS, galvanized square steel with high quality galvanizing, have superior anticorrosion and anti-friction qualities in our range, offering a substantial advantage in this respect.

For general-purpose use, our ms sheets (mild steel sheets) offer the optimal balance between strength and workability. In conjunction with our slotted angles, the components provide an opportunity for designing flexible and easily adjustable storage systems and frameworks.

Flexible and easily adjustable slotted angles

It is highly durable and comes in slotted angles which are used for a variety of structural applications: shelving units, lightweight frames, and so on. Easy to assemble and modify in an industrial or commercial setting, they are widely popular.

Whether working on robust frameworks, solar installations, or storage solutions, we are your trusted partners at Parco Engineers. We provide an extensive range of stainless steel handrail, base plates, round bars, galvanized square steels, solar structures, solar panel structures, structural solar panels, cold-rolled sheet, cr sheet, slotted angles, ms sheets, and gp sheets for your every need.