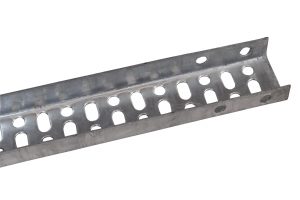

Power generation, oil and gas, petrochemical, steel, data centers, telecommunications, and infrastructure sectors are some of the industries that regularly use ladder cable trays. These industries have intricate and heavy-duty electrical systems. Its durable build and low weight make the fiber optic cable tray perfect for harsh environment applications of long cable distances and multi-cabling. GI type ladder cable trays are well-received across marine and seacoast-based industries because of their corrosion-proof property. These sectors are taken care of by Parco Engineers through high-graded, client-specified cable ladder solutions.