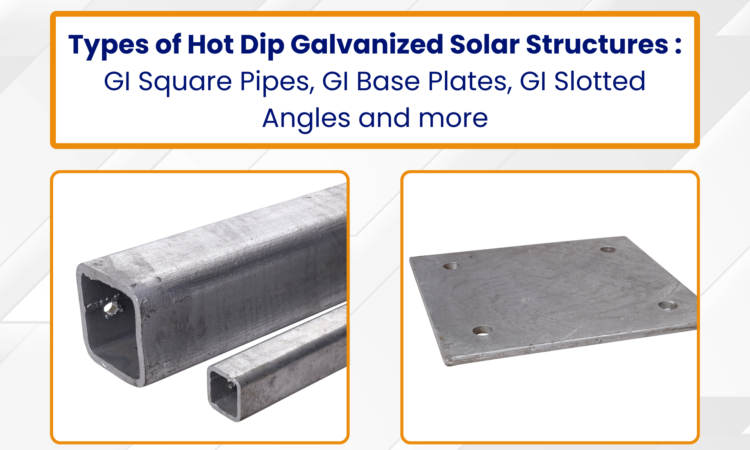

Types of Hot Dip Galvanized Solar Structures : GI Square Pipes, GI Base Plates, GI Slotted Angles and more

Solar energy is a backbone of sustainable development, and robust infrastructure is required to harness it efficiently. Among the main components of a solar installation are the solar structures that support and stabilize the panels. At Parco Engineers, we specialize in high-quality, hot dip galvanized (HDG) solar structures designed for durability and performance. This blog explores the various types of galvanized solar structures, their uses, and the advantages they bring to solar installations.

Why Hot Dip Galvanized Solar Structures?

Hot dip galvanization is a process where steel is coated with zinc to prevent corrosion, making it ideal for solar structures exposed to harsh weather conditions. A solar panel structure endures years of environmental wear and tear, and galvanization ensures longevity and minimal maintenance.

Key Types of Hot Dip Galvanized Solar Structures

1. GI Square Pipes

- Corrosion resistance due to the zinc coating.

- High tensile strength to withstand strong winds and other environmental conditions.

- Versatile design for both ground-mounted and rooftop solar panel structures.

At Parco Engineers, our GI square pipes come in various dimensions to meet the unique requirements of different solar projects.

Features and Benefits:

Galvanized square steel pipes are a fundamental component in solar mounting structures. These pipes provide exceptional strength and stability, making them ideal for framing and supporting structural solar panels.

2. GI Base Plates

- Enhanced load-bearing capacity.

- Corrosion-resistant surface for long-term use.

- Easy installation and compatibility with various solar mounting designs.

Our steel base plates are precision-engineered for reliability and durability, ensuring your solar setup stands the test of time.

Advantages:

A base plate serves as the foundation for securing solar structures to the ground or rooftops. Made from high-quality galvanized steel, base plates ensure the stability of the entire installation.

3. GI Slotted Angles

- Supporting smaller solar panel structures.

- Creating flexible mounting configurations.

- Securing additional components like inverters or batteries.

Their flexibility and ease of use make slotted angles a favorite choice among solar engineers and installers.

Applications:

GI slotted angles are another versatile component used in solar installations. They allow for adjustable connections and are commonly used in framing and mounting systems.

4. GI Round Bars

- Superior corrosion resistance.

- High strength-to-weight ratio.

- Long lifespan, even in extreme weather conditions.

Why Choose GI Round Bars?

GI round bars, also known as galvanized round bars, are widely used for structural and reinforcement purposes in solar projects. These bars add strength and stability to the overall design.

5. Strut Channels and Unistrut Channels

The strut channels are otherwise known as unistrut channels, which provide essential mounting support to the solar panels. The strut channels can bear heavy loads and are quite flexible for mounting purposes.

Important Features:

- Modular structure that allows for easy assembly

- High corrosion resistance to withstand outdoor environments

- Easy to fit in mounting brackets and other fittings.

Strut channels are particularly useful for commercial and industrial solar installations where adaptability is essential.

6. Custom Components

We also offer bespoke components at Parco Engineers:

- Steel base plates for one-off mounting requirements

- Specialty galvanized round bars for reinforcement

- Customized solar panel structures that are dimensionally designed for your project

Benefits of Hot Dip Galvanized Solar Structures

Hot Dip Galvanized solar structures offer numerous benefits when incorporated into your solar installation:

Resistance to corrosion: through the application of zinc, making the structure resistant to rust, and therefore increasing the life expectancy of your solar mounting structure

Strength and Durability: HDG components can withstand extreme weather conditions, ensuring stable performance over decades.

Sustainability: Galvanized steel is recyclable, making it an eco-friendly choice for renewable energy projects.Versatility: Components like GI square pipes, strut channels, and base plates can be tailored to suit different project requirements.

Applications of Hot Dip Galvanized Solar Structures

Residential Solar Systems:

Homeowners rely on compact, durable GI structures for solar panels to maximize rooftop efficiency.

Commercial and Industrial Solar Projects:

For large-sized installation, a solid solar mounting structure is needed. It may comprise galvanized square steel or unistrut channels.

Open-Field Solar Farms

It demands heavy-duty frames, GI pipes, and reinforced steel base plates to support the firm installation of a solar farm.

Why Parco Engineers?

We are an experienced manufacturing company that produces GI structures for the installation of solar panels. We Facilitates tailormade to individual project specifications.

We provide competitive pricing and timely delivery. We deliver uncompromised commitment to quality and sustainability.

When it comes to building durable, reliable, and efficient solar panel structures, hot dip galvanized components are the gold standard. Whether you need GI square pipes, steel base plates, or strut channels, Parco Engineers has the expertise and products to power your renewable energy projects.

Invest in the future of energy with Parco Engineers, your partner for sustainable infrastructure. Contact us today to learn more about our complete range of solar structures and solutions.

3 Replies to “Types of Hot Dip Galvanized Solar Structures : GI Square Pipes, GI Base Plates, GI Slotted Angles and more”

Comments are closed.