Different Types of Hot-Dip Galvanized Products and Their Applications

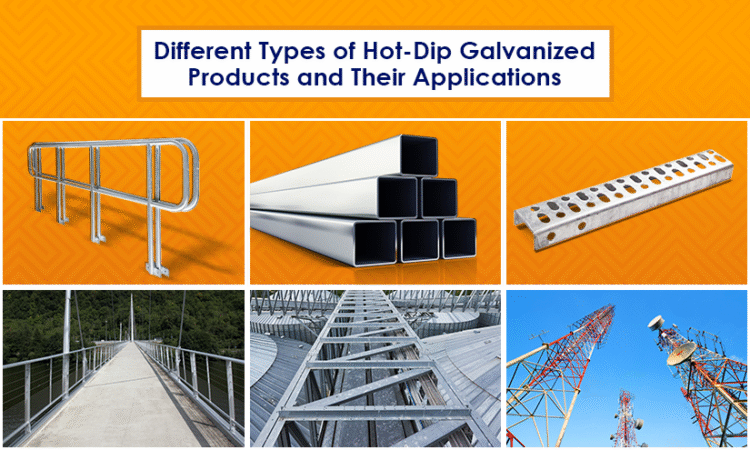

With modern infrastructure and industrial development, nothing is more important than durability and safety. Hot Dip Galvanized Products have become a reliable option for engineers, architects, and contractors who need long lasting performance in tough conditions. Parco Engineers is in the business of providing an extensive line of galvanized products meant to address varied requirements across industries like construction, power, telecom, transportation, and industrial plants.

In this blog, let us take a closer look at the different types of Hot Dip Galvanized Products, their properties, and how they are used in real-world applications.

Beams, Angles, and Channels

One of the most widely used structural components in any project is the GI angles and beams. Known for their load bearing capability and corrosion resistance, these products are essential in the construction of bridges, warehouses, and factory frameworks.

Among them, the hot dip galvanized angle is one of the most versatile options since it not only provides strength, but also rust resistance, making it suited for outdoor and industrial applications. Likewise, C shaped channels or commonly referred to as galvanized C channel or Gi C channel, provide more flexibility towards support structures, cable management, or solar panel mounting systems. Their simplicity of installation and superior tensile strength make them in great demand in both residential and commercial building projects.

Gratings and Flooring Solutions

For safe walking platforms that industries and buildings need, gratings are a vital component. As a seasoned grating manufacturer, Parco Engineers provide a variety of products, such as GI grating and electroforged gratings.

Electroforged gratings are particularly favored in chemical plants, power plants, and offshore platforms where non-slip surfaces and strength are paramount. Secondly, industries also need checkered plate or checker plate sheet floor solutions. These anti-slip surfaces that come in the form of hot dip galvanized checker plate make workers safer where the risk level is high, as in the case of oil refineries, construction sites, and shipyards.

By balancing durability and functionality, gratings and checker plates serve both structural integrity and safety access routes.

Cable Trays for Electrical Installations

Electrical installations in industries and tall buildings demand systematic and secure cabling management. This is where the function of cable trays comes into play. Parco Engineers is a reliable perforated cable tray manufacturer, providing a diverse range of cable trays that can be tailored to suit particular project needs.

The hot dip galvanized perforated cable tray, and the GI perforated cable tray are used to carry power and data cables while facilitating heat dissipation and inspection. They find extensive application in power distribution plants, IT complexes, and metro projects. In addition to these, the steel cable tray and the galvanized cable tray provide strength and durability for heavier loads.

For applications demanding stronger cable support, our ladder type cable tray also known as ladder cable tray or cable ladder, provides superior ventilation for power cables. These are offered in hot dip galvanized ladder cable tray and GI ladder cable trays, which make them a durable option for industrial installations where reliability and safety are of prime importance.

Earthing Materials

Earthing systems play a crucial role in electrical safety within any infrastructure development. Products such as earthing flats and earthing rods are used to ground the structures to prevent electrical surges and short circuits. Hot dip galvanization makes these products longer lasting and better conductors, which guarantee people and machinery safety from electrical risks.

These products are widely used in power plants, residential communities, and business centers and these are a major component of current infrastructure.

Handrails and Safety Components

In commercial buildings, public infrastructure, and industries, safety elements such as handrail systems play a key role. Handrails that are hot dip galvanized not only offer protection from corrosion but also ensure structural integrity. In high-end projects, stainless steel handrail choices are also common, especially in interior and architectural uses where appearance is of concern.

In addition to handrails, base plate solutions are employed to anchor structural members firmly. Solutions such as GI base plate and hot dip galvanized base plates are long-lasting and withstand even under extreme outdoor conditions, making them a necessary component in safety-conscious settings such as industrial platforms, staircases, and bridges.

Pipes and Tubular Products

Pipes find application in water supply, scaffolding, and industrial support systems. Parco Engineers is one of the trustworthy GI pipe manufacturers, providing a variety of tubular products.

The GI round pipe and hot dip galvanized round pipe are widely employed in plumbing, irrigation, and scaffolding because of their corrosion-resistance. In the same way, the GI square pipe offers strength and versatility for frames, fencing, and support structures. Because of their longer service life, these pipes minimize maintenance costs while guaranteeing dependability.

Slotted Angles and Unistrut Channels

For flexible frames, storage systems, and modular racking, slotted angles are absolutely necessary. We at Parco Engineers provide top-notch slotted angle iron made to precision. Being a prominent slotted angle manufacturer, we make sure these products are simple to assemble and customize, making them perfect for warehouses, retail storage, and industrial shelving.

Complementing slotted angles, the Unistrut channel also provides an effective means of supporting wiring, piping, and HVAC systems. With its modular design, it is easy to install and adjust, thus it has become a popular choice for electrical and mechanical installation in contemporary buildings.

Why Parco Engineers' Hot-Dip Galvanized Products?

In manufacturing hot dip galvanized products, quality and dependability come first. Parco Engineers has the goal of providing products with international standards of performance and safety. Its galvanization process is high-tech, which guarantees even zinc coating, high corrosion resistance, and extended service life.

From GI angles to hot dip galvanized base plates, and from GI cable tray manufacturer solutions to grating manufacturers, our array of products caters to every commercial and industrial need. With years of experience and uncompromising customer satisfaction, Parco Engineers is a reliable partner for projects all over India and the world.

Hot-Dip Galvanized Products are the pillars of today’s infrastructure, providing safety, durability, and performance across various applications. From hot dip galvanized angle for structural integrity, GI grating for floor safety, hot dip galvanized ladder cable tray for electrical reliability, or slotted angles for storage efficiency, all products contribute to establishing a sustainable future.

We at Parco Engineers pride ourselves on providing an extensive portfolio of galvanized solutions designed to address the changing requirements of industries. With innovation and quality, we continue to enable the development of sustainable and safe infrastructure.