Delivering Superior Corrosion Protection with World-Class Hot Dip

Galvanizing Standards for Over 25 Years

Trusted by over 1500+ clients across India’s infrastructure, engineering, and renewable sectors.

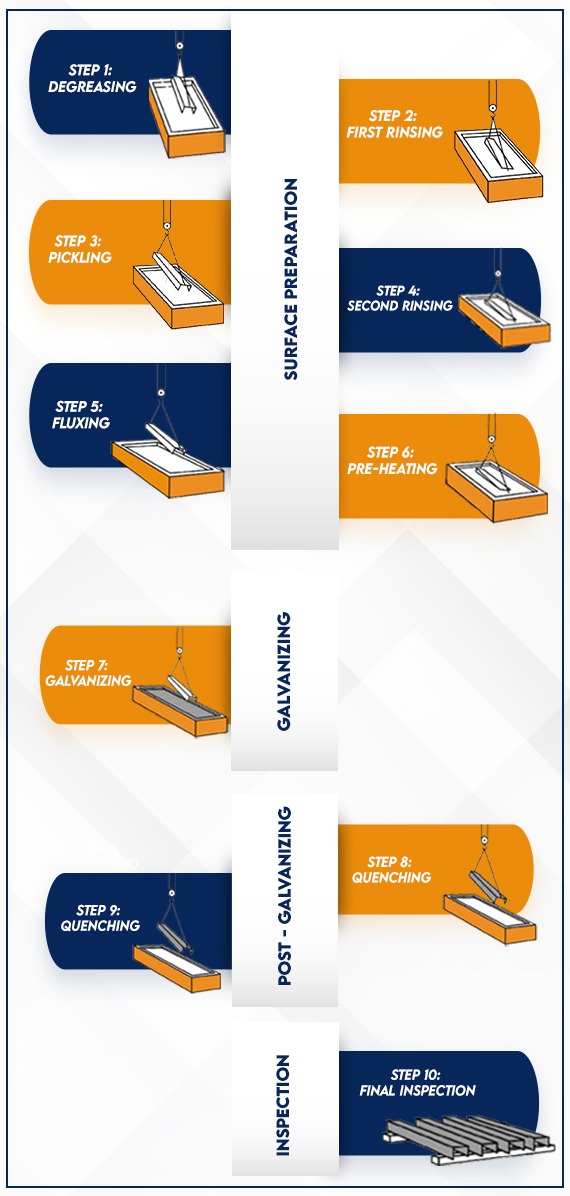

Hot dip galvanizing is a protective coating process in which steel or iron is immersed in a bath of molten zinc at around 450°C (840°F). This process creates a strong, corrosion-resistant layer that bonds metallurgically to the base metal, protecting it from rust, moisture, and environmental damage.

Steel is cleaned using an alkaline or acidic solution to eliminate dirt, oil, grease, and industrial residues. This step ensures the surface is perfectly clean for the next chemical treatment

Steel is rinsed with clean water to remove any remaining cleaning agents, preventing interference with the pickling process.

The steel is immersed in acid to remove rust, scale, and oxidation.This exposes clean, bare steel for better zinc adhesion during galvanizing.

A thorough rinse removes all acid traces and contaminants to prevent weakening of the zinc coating.

Steel is dipped into a zinc ammonium chloride flux solution. This removes any last traces of oxides and coats the steel with a protective layer that prevents oxidation before galvanizing.

Steel is heated to remove all moisture and prepare the surface for immersion in molten zinc. This step reduces splashing and improves coating uniformity.

Steel is submerged in a bath of molten zinc (around 450°C). A metallurgical reaction occurs, forming multiple zinc-iron alloy layers for long-term corrosion protection.

Once removed from the zinc bath, steel is cooled by air or water to solidify the zinc coating and make handling safe.

A thin protective chemical layer is applied to prevent white rust and protect the zinc finish during storage and transport.

The galvanized steel is checked for coating thickness, adhesion, surface finish, and defects. Any irregularities are corrected before dispatch.

Galvanized pipes for architecture, plumbing, solar structures, etc

Hot dip galvanizing is widely used to protect steel from rust and corrosion in outdoor and industrial environments. Common applications include:

Our galvanization ensures durability across high-corrosion, coastal, industrial, and high-load environments

With over 25 years of industry experience, Parco Engineers is equipped with a large production capacity and a specialized team dedicated to delivering high-quality galvanization. Our streamlined processes ensure fast turnaround times, while our competitive pricing makes us a trusted choice for projects of all sizes. Whether handling small custom batches or large industrial fabrications, we consistently meet client expectations—earning the trust of leading government and private sector companies across India.

Galvanized steel typically lasts 40–70 years, depending on environmental conditions. Its zinc coating provides long-term protection against rust, moisture, and corrosion.

Parco Engineers delivers a uniform zinc coating of 80–120 microns, ensuring strong, durable, and industry-standard corrosion protection.

Yes, pickup and delivery services are available as per mutual terms agreed with the customer.

Ans: There is no minimum size limitation. The maximum size we can galvanize is up to 7 meters long of materials.

Absolutely. Hot dip galvanizing is ideal for coastal and high-humidity environments, offering superior resistance to saltwater corrosion.

Parco Engineers follows international galvanizing standards, including IS, ASTM, and BS specifications, ensuring high-quality and reliable coating performance.

[forminator_form id=”2481″]

[forminator_form id=”2481″]