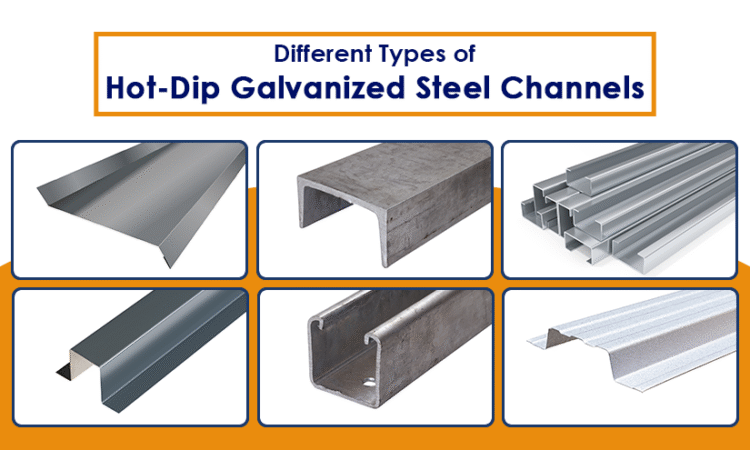

Different Types of Hot-Dip Galvanized Steel Channels

In structural steel solutions, the steel channels are key elements commonly employed in construction, infrastructure, and industrial projects. Where durability, corrosion resistance, and long life are of high concern, hot-dip galvanized steel channels are the first choice. Here at Parco Engineers, we are experts at providing hot-dip galvanized channels in a broad range to suit different industrial requirements and provide maximum performance in demanding conditions.

Before getting into the types, let’s answer the basic question:

What is a steel channel?

A steel channel is a roll-formed metal strip that features a U or C-shaped cross-section. Those channels provide structural support and work as foundational elements in construction, fabrication, and framing. Galvanizing these channels through the hot-dip process coats them with a protective layer of zinc, enhancing their ability to resist corrosion.

Types of Steel Channels

While there are various types of galvanized steel channels available, Parco specialize in manufacturing high-quality C channels and strut channels to meet a range of structural and engineering requirements.

1. C Channels / C shaped Channels

C Channels are also known as ‘parallel flange channels,’ and are structurally composed shapes made from steel that resembles the letter “C.” C channels are used in construction and in industrial applications because of their ability to support a large amount of weight, especially in situations like floor systems, frames, bracing, purlins and equipment support structures. C channels also are available in a version that is made with hot dipped galvanized steel, which makes them more resistant to environmental degradation. Hot dipped galvanized Channel is produced by the full immersion of the MS channel in molten zinc. This process allows for the creation of a metallurgical bond that is resistant to rust, corrosion, and wear—in outdoor or high moisture areas, far exceeding the performance of non-galvanized steel. As galvanized C channels have qualities of being exposed to the elements, they make ideal types of infrastructure for a wide variety of scenarios including bridges, highways, roofing frames, and marine infrastructures. A more robust profile and as a completely zinc coated product means the C channel has a longer service life, requires less maintenance cost, and performs consistently over time. The inherent versatility and corrosion resistant attributes of C channels have also made them popular in the manufacturing of solar mounting systems, as cable tray support systems, as brackets in industrial machinery frames, among other applications. Their constant geometry and compatible surfaces with other structural components lend them to collaborating together in many engineering and fabrication endeavors.

Applications: Building frame structures, bridge trusses, cable management systems, and railway systems.

2. Strut / Unistrut Channels

Strut Channels, also widely known as Unistrut, is a type of U-channel steel framing element. Strut channels are typically used to mount, support, and connect lightweight mechanical, electrical, and plumbing systems, and are typically manufactured with slotted holes or perforations to facilitate adjustment, versatile modular assembly using bolts, brackets, etc., and service without welding, grinding, cutting, or special tools. Hot-dip galvanized strut channels are really useful and can protect against corrosion where this would otherwise be a critical risk (e.g. industrial plants, rooftops, power facilities, HVAC systems and offshore platforms). Hot dipped galvanizing using molten zinc is an appropriate approach to anti-corrosion than other methods. In this instance, the zinc coating seals the surface of the strut channel and helps prevent moisture and atmospheric elements from reaching the base metal. Having enhanced durability and longer service life.

Due to the unique characteristic and versatility of strut channels, they can be used for both temporary or permanent applications. Hot dipped galvanized strut has shown the ability to be used to suspend cable trays, support conduit pipes, frame solar panels, etc., while maintaining structural integrity, and being easy and flexible when configuring on site.

Applications: Pipe supports, cable tray supports, HVAC systems, and equipment frames.

3. U Channel / U Shaped Channel

U channels have an open, uncomplicated cross-section that allows them to be easily incorporated into structures as enclosures, edge protectors, or tracks. Hot dip galvanized U channels are typically used where both strength and aesthetic looks are needed.

Applications: Enclosures, window and door frames, machine parts, edge protection.

4. Z Channel / Z Shaped Channel

Z channels are regularly applied in roofing and wall constructions because of their overlapping capability. Galvanized Z channels are used primarily because they are versatile and easy to install.

Applications: Wall studs, purlins, and roofing panels.

5. Hat Shaped Channel

The hat channel has an unusual profile resembling a hat which contributes to great load distribution. The channels are applied in furring, siding, and ceilings. Galvanized extends their applications to exterior and moist environments.

Applications: Interior and exterior wall furring, roof deck support, panel systems.

6. Sigma Channels

Sigma channels are heavy structural members that provide an excellent strength-to-weight ratio. These are common in heavy-duty frameworks and industrial machinery bases.

Uses: Racking systems, bridges, heavy-duty enclosures, machinery frameworks.

7. Lipped Channels / Lip Channels

The addition of lips on these channels provides improved stiffness and load-bearing capability. Our galvanized lipped channels are engineered for added structural integrity and corrosion resistance.

Uses: Truck trailers, shelving systems, frames in commercial and industrial facilities.

8. Custom Fabricated Channels

At Parco Engineers, we also manufacture custom fabricated channels tailored to unique project requirements. Whether it’s a special shape or dimension, we provide fully galvanized solutions to match your specifications.

Uses: Custom structures, prototypes, architectural elements.

Applications of Galvanized Steel Channels

The wide variety of types of steel channels makes them applicable in several key sectors:

1. Industrial Plants

In factories and processing plants, galvanized iron channels are used in frameworks, platforms, equipment supports, and cabling structures. Their corrosion-resistant nature makes them ideal for chemical and high-moisture environments.

2. Bridges

Steel channels, particularly hot dip galvanized channels, play a vital role in the construction of bridges by supporting decks, barriers, and drainage systems. Their high strength and anti-rust coating make them suitable for long-term exposure.

3. Commercial Buildings

From HVAC systems to wall partitions, galvanized channels and strut channels offer reliable support structures within offices, malls, hospitals, and educational institutions.

Why Choose Hot-Dip Galvanized Channels from Parco Engineers?

Superior Corrosion Resistance: Our hot dipped galvanized channels ensure long-term protection against rust and oxidation.

Compliance & Quality: Manufactured as per industry standards and subjected to rigorous quality checks.

Large Product Range: We have a wide range of channels available in various sizes and specifications.

Custom Solutions: We have custom fabricated channels for special project needs.Understanding the types of steel channels and their applications helps in choosing the right structural component for your project. Whether you need a galvanized C channel, or a gi slotted C channel, Parco Engineers provides reliable, high-quality products tailored for performance and durability.

Trust Parco Engineers for all your galvanized channel needs — where strength meets sustainability.

2 Replies to “Different Types of Hot-Dip Galvanized Steel Channels”

Comments are closed.